Automatic chemicals and auxiliaries powders dosing

Request more information / quote

Hoppers of various capacities

The hoppers are used to feed the conveyor systems with the products to be dosed, whether in powder or granular form. They are built both in AISI 304/316 stainless steel and in anti-corrosion plastic material such as PP ( polypropylene ) or PVC ( Polyvinyl chloride ) , depending on the need. The geometries and dimensions may vary according to the project. all the hoppers can be equipped with a support frame, a hood for suction of residual dust as well as various accessories such as: Vibrators , bridge breakers , level probes, etc.

ACCESSORIES

- Mechanical bridge breakers in various configurations

- Electrovibrators with adjustable eccentric masses

- Vibrators or pneumatic hammers

- Fluidizing porous sets

- Rotary vane level indicators

- Capacitive sensors

- Membrane level indicators and other more specific ones

Request more information / quote

Flexible screw conveyor

The flexible screw conveyors , particularly suitable for powder dosing and granule dosing, are widely used in the food, chemical, pharmaceutical, cosmetic and plastic industries. blends.

They are made with 40 mm external diameter tube. to 125 mm. and suitable for the characteristics of the transported material. Capacity from 120 kg / h to 10,000 kg / h The actual capacity is also a function of:

Spiral rotation speed

-

-

Inclination to pick up

-

Smoothness of the material

-

Type of withdrawal: suitably shaped hopper, silo, drum, pile.

-

This transport system is able to:

-

- Do not demix, during transport, mixed and dosed products.

- Homogenize while transporting.

- Lending itself to multiple combinations.

- Do not pollute because it is hermetic and mechanical.

- Ensure silent operation in the workplace.

- Easily fit into existing systems because it is flexible.

- Upload and download anywhere along the route.

- Overcome significant differences in height and cover considerable distances.

- On request special executions and in compliance with ATEX 949 / CE directive for Zone 2 – 22 and Zone 1 – 21

Withdrawal is assumed with:

– Conveyed material: free flowing granular powder

– Regular continuous flow

– Apparent specific weight 1 kg / dm³

– Initial pick-up stroke with inclination α = 30 °

– Rotating spiral at 580 rpm.

(930 rpm applications are also possible)

* For the flow rate in kg / h multiply for the specific weight of your product. product

The transport potential is linked to many variables and therefore the tabulated values are purely indicative, please contact our. technical office for your specific application.

MODEL | FLOW LITERS / HOUR |

MAR 40 | 140 |

MAR 55 | 400 |

MAR 65 | 850 |

MAR 70 | 1250 |

MAR 80 | 1800 |

MAR 90 | 2500 |

MAR 100 | 3500 |

MAR 110 | 4600 |

MAR 125 | 7500 |

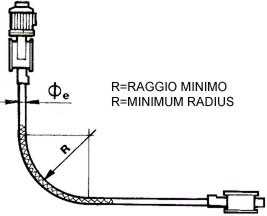

MODEL -De (mm) | R (mm) |

40 | 1000 |

55 | 1400 |

65 | 1600 |

70 | 1800 |

80 | 2500 |

90 | 2800 |

100 | 3000 |

110 | 3800 |

125 | 4500 |

Request more information / quote